Grants Precision ISR

Environmentally Responsible Uranium Recovery

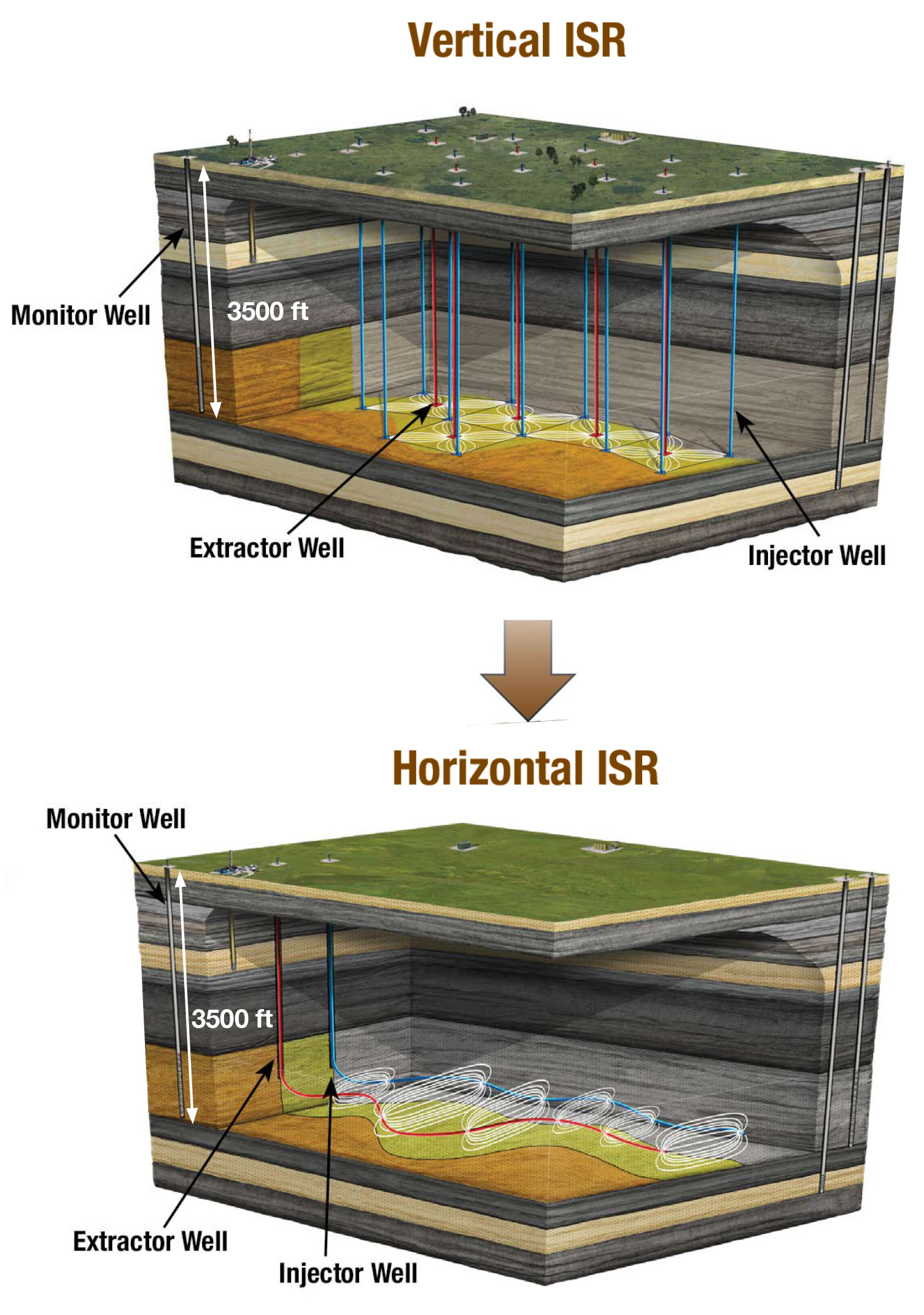

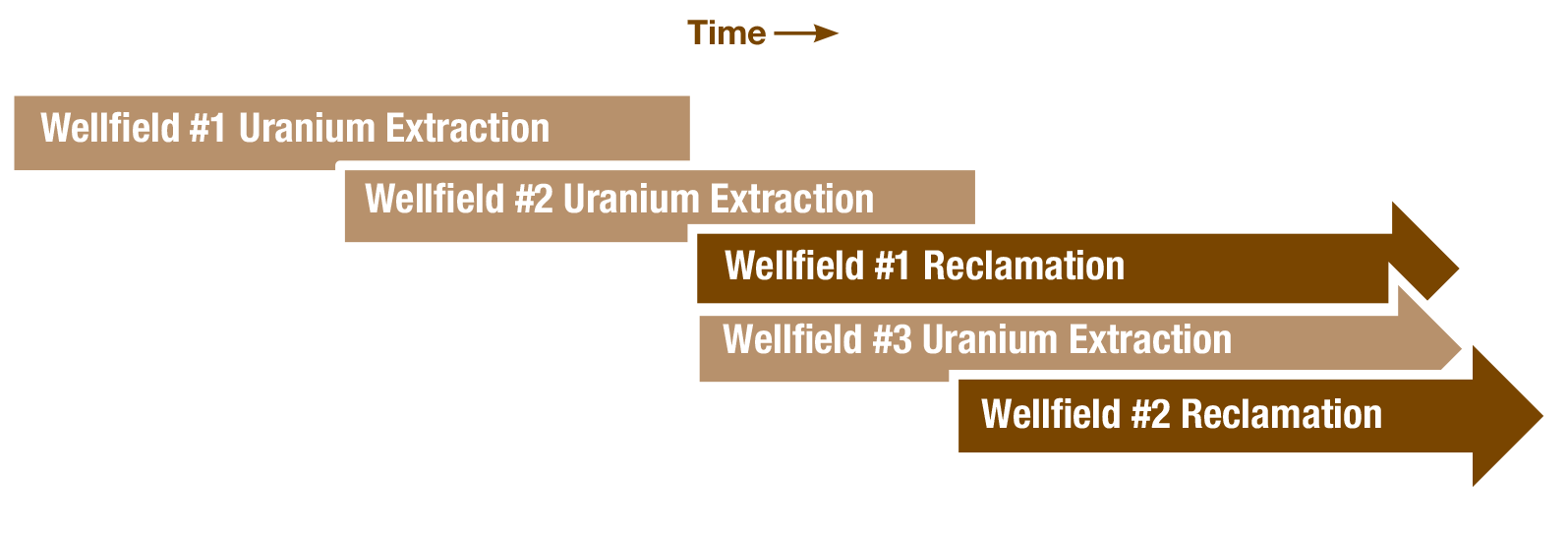

At Grants Energy, we're reimagining how uranium is extracted to power the future. Our approach combines In-Situ Recovery ("ISR")—a safe, environmentally friendly method of uranium extraction—with the use of horizontal wells, a technique commonly employed in oil and gas production. By merging these two proven technologies, we can extract uranium more efficiently and with minimal environmental impact.

View BrochureThe Technology

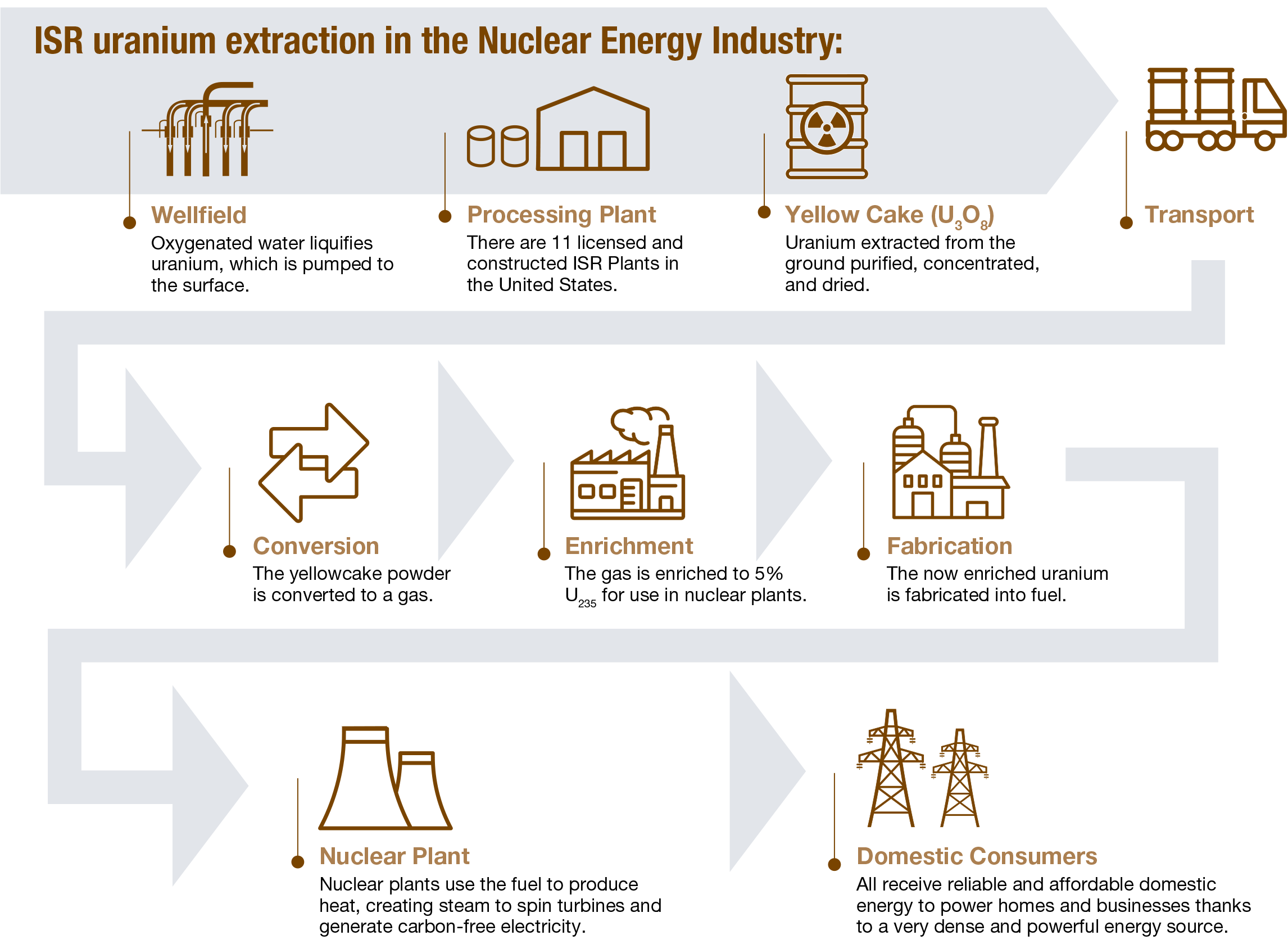

About In-Situ Recovery

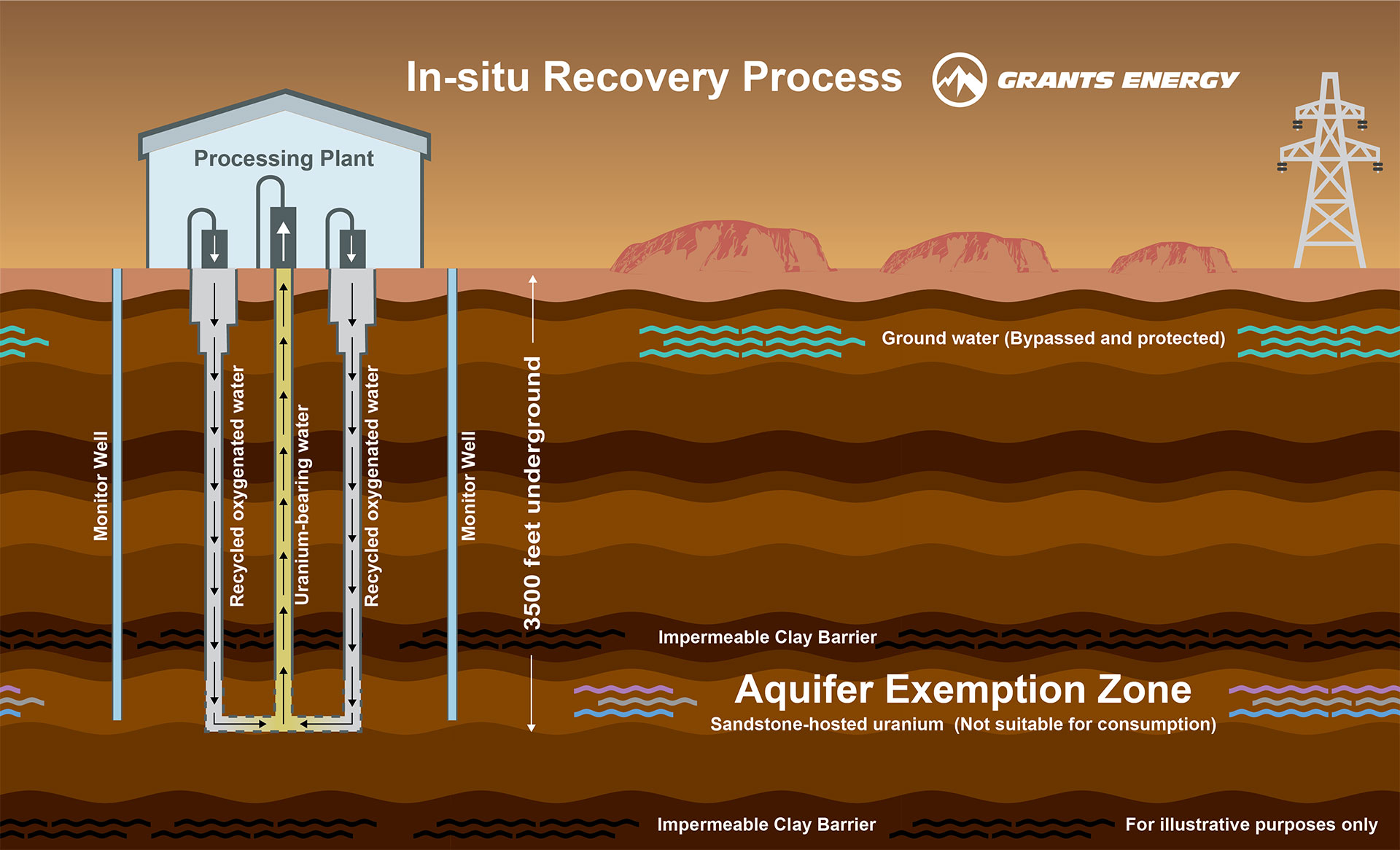

In-Situ Recovery (ISR) is a proven, safe, and eco-friendly method of uranium extraction that returns the groundwater and land back to its original purpose and use once finished. ISR has been safely used around the world for over 50 years with minimal environmental impact.

Today, ISR accounts for about 60% of global uranium production. ISR is highly regulated in the United States by federal and state agencies. Operations are conducted under strict environmental standards. ISR is designed with multiple layers of protection to prevent contamination of groundwater. The groundwater solution used in ISR typically includes a mild bicarbonate (just like the baking soda found in your kitchen cabinet) and oxygen (in the air you breathe).

Utilizing ISR technology, Heathgate Resources, an affiliate of Grants Energy, has safely produced more than 40 million pounds of uranium oxide in South Australia, contributing $7.5 billion to the local economy to-date. Heathgate is a world leader in advanced ISR mining technology, committed to environmentally sustainable uranium exploration and extraction. The Grants Precision ISR project will build upon the expertise, knowledge, and diligence of the South Australian operations.